The content of the article:

- History of appearance

- Device and principle of operation

- Suspension scheme

- Advantages and disadvantages

- The main differences

- MacPherson suspension signs and malfunctions

- Where is installed

- Price

- Reviews

The car's suspension is one of the main components of the running system, due to which the car moves. One such example is the MacPherson suspension, which is part of the front wheel drive vehicle. This is one of the most common types of independent suspension, moreover, it is not very whimsical in terms of spare parts and breakdowns. We can also say that McPherson is a developed type of double wishbone suspension, in which the engineers installed a shock absorber instead of the upper wishbone.

Due to its compact structure and few parts, the MacPherson suspension allows the engine and transmission to be positioned transversely, and the torque is usually transmitted to the front axle of the vehicle. Another plus for McPherson is the large move to prevent breakouts. Let's consider in more detail the suspension device, characteristics and possibilities in pros and cons.

How and when the MacPherson pendant appeared

As already mentioned, the modern MacPherson suspension has gone through more than one modification and showed good results. The ancestor of this type is considered to be a double wishbone suspension. The system got its name in honor of the design engineer of the General Motors company - Earl Styles MacPherson, who developed all the mechanisms and introduced them into cars.

For the first time, they started talking about the MacPherson suspension back in the 40s of the last century. It was then in 1948 that it was first tested and installed on the production model Ford Vedette 1948. Over time, after the death of the design engineer (the years of Earl MacPherson's life - 1891-1960), the modified version began to be used on other cars of the brand, and from the beginning In the 70s, McPherson's suspension was taken up by other manufacturers for their cars.

The device and principle of operation of the MacPherson suspension

No less interest in the very structure of the suspension mechanism, as well as its principle of operation. As mentioned above, the progenitor of this type was the double wishbone suspension, which also belongs to the class of independent suspensions. A characteristic feature of this type of mechanism is the presence of a spring in its upper part. Engineers also distinguish 5 main parts of the difference between the strut and a conventional shock absorber:

- large stem diameter and reinforced construction;

- the ability to keep the weight of the car;

- the mechanism is more complex;

- an elastic element capable of absorbing the load from the road surface;

- the swivel support is used in turning the car wheel;

- perceives lateral and axial loads and load drops.

Among the main mechanisms of the MacPherson suspension are:

- stretcher;

- anti-roll bar;

- shock absorber rack;

- rounded fist;

- wishbone

Now about each detail in order, what they are intended for and what role they play in the mechanism. Consider first stretcher, since it is considered the supporting element of the entire system. The subframe is attached to the car body using silent blocks. Due to such rubber-metal elements, engineers were able to reduce the transmission of vibration to the car body and reduce noise.

In turn, the steering gear, anti-roll bar and supports are attached to the subframe. wishbone... The side part of the subframe was also not left aside, the wishbones of the left and right wheels are attached to it. As a rule, the fastening of such levers is double and gives the entire structure, in the longitudinal direction, special rigidity. Finally, the engineers attached a steering knuckle to the other end of the wishbone using a ball joint.

Moving further down the MacPherson strut mechanism, attached rounded fist to the steering rod due to the articulated connection. The most upward steering knuckle is attached to the shock absorber strut, the lower part is connected to the wishbone. In addition, it houses a bearing assembly (wheel bearing and wheel hub) and a brake caliper.

The next component of the MacPherson suspension is shock absorber, simultaneously combining a pair of mechanisms at once: a metal spring and a shock absorber located on the same axis with a compression buffer. Due to the latter, it is possible to change the linear characteristics of the elasticity of the spring of the shock absorber strut. The lower part of the strut is connected to the steering knuckle, the upper part is attached to the mudguard of the wing due to rubber bushings. It should be understood that this particular mechanism depends on the manufacturer, some manage to separate the shock absorber and the spring into two separate structural elements.

Another integral element of the MacPherson suspension is anti-roll bar... The main purpose of the mechanism is to reduce the side rolls of the vehicle as a whole. The stabilizer itself is attached to the subframe by means of two supports, but the ends of the stabilizer are attached to the shock absorber struts due to the hinged connection.

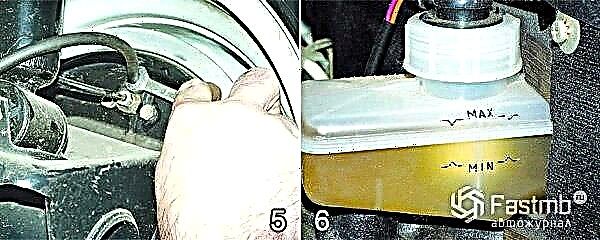

In the photo, McPherson strut shock absorbers

Having considered the MacPherson suspension arrangement, consider principle of operation the entire system. What moves in what order and what to expect if the rules are not followed. In the event of a collision with an obstacle, or unevenness, the car wheel is displaced in the vertical direction relative to the body. The spring of the shock absorber strut and the lever are compressed, which are attached by movable joints to the bearing part and the wheel hub.

The main impact falls on the spring, but since it is not able to quickly absorb the impact, a shock absorber comes to the rescue, absorbing all the impact energy. In addition to energy, a force acts on the car wheel, due to which the wheel is displaced in a horizontal position (longitudinal direction). So that the wheel remains in place, two levers are responsible for this, installed at an angle or one A-shaped (depending on the manufacturer). In the case of an A-arm, two tops are attached to the body and one tops are attached to the hub itself.

Having overcome the unevenness, the reverse process begins. The spring of the suspension strut returns to its original position, due to which the wheel begins to align itself with the car body. It should be understood that while overcoming irregularities, each wheel is displaced independently of each other. No matter how manufacturers claim that MacPherson's suspension copes well with irregularities, some of the impacts are still transmitted to the car body.

If both wheels of the car move over bumps, then, despite the softness of the springs and the quality of the shock absorbers, the car body can swing from side to side. In this case, engineers use an anti-roll bar, which links two independent suspensions of one axle into one whole. There are no special forms, this is a normal torsion bar, which, due to the appearance of different forces, prevents twisting and dampens body vibrations on the sides.

MacPherson suspension scheme

- Shock absorber spring;

- Shock absorber;

- Lower arm;

- Anti-roll bar;

- Steering rack;

- Tie Rod;

- Wheel hub;

- Support bearing;

- Half-axles (wheel drive);

- Spherical bearing.

Pros and cons of MacPherson suspension

As with every device, the MacPherson strut has its own pros and cons when compared to other independent suspension types.To begin with, consider the main advantages that engineers and specialists most often highlight, since this suspension is widely used on modern cars:

- Reliability, and the simplicity of the design itself provides a very long service life;

- Versatility, the MacPherson suspension works great on both the front and rear axle of the vehicle;

- Relatively low production cost. The small number of components makes this suspension the most affordable and inexpensive;

- Small size. Due to the small number of parts, it can be used even on the most compact cars;

- Suspension travel with plenty of headroom. Due to such a margin, the likelihood of a suspension breakdown or the transfer of impact energy to the car body is reduced;

- The load on the moving suspension elements has been reduced. The main effort is taken by the rack, but the ball bearings and silent blocks provide the mobility of the mechanisms, due to which they received a good supply of resources.

Despite such advantages of the MacPherson suspension, there are still disadvantages that have played an important role in mass use on all cars:

- Difficulty in maintaining the suspension strut. In order to replace one part or carry out maintenance of other components, it is necessary to completely remove the entire structure, but for disassembly you will need a special tool, since it is not so easy to compress and unclench the spring;

- Constant load on the rack. It is this factor that affects the life of the suspension, as a rule, it is proportional. The greater the load, the shorter the service life;

- Camber and kinematics. In the case of a large travel of the shock absorber strut, the camber-toe angles vary over a wide range. As a result, the stability and controllability of the vehicle is reduced, and tire wear increases;

- Reinforcement of the attachment point on the body of the upper part of the shock absorber strut. We can say that this part of the body most of all withstands overloads, if not strengthened, then cracks or corrosion may appear;

- Increased operating noise. Due to noisy mechanisms, MacPherson suspension is not used on premium cars; most often, preference is given to the multi-link version. This type of suspension ensures quiet and smooth ride of the car body.

Considering the pros and cons of the MacPherson suspension, they decided to use it on many production cars, as one of the independent suspension options. Cheap, simple and reliable, which gives it its popularity. In addition to the standard set, there are also modified options. In this case, instead of the standard shock absorber, the manufacturer installs a hydropneumatic shock absorber. Due to this refinement, you can change the stiffness of the suspension, install an additional ball joint on top. In turn, this affects the improvement of handling, in the case of movement on bumps on the road.

The main differences between the MacPherson suspension

The MacPherson pendant is one of a variety of independent types. The peculiarity of such a system is that it is installed separately on each wheel, and the differences can be found in almost everything.

| Differences between MacPherson suspension and multi-link | |

| McPherson | Multi-link |

| Shock absorber | Telescopic stand |

| Lower arm | Guide lever |

| Half-axles (wheel drive) | Half-axles (wheel drive) |

| Support bearing | Rack support |

| Wheel hub | Wheel hub |

| Spherical bearing | Upper levers |

| Steering rack | Swivel stand |

| Tie Rod | Wheel bearing |

| Shock absorber spring | Stabilizer bar |

| Anti-roll bar | Anti-roll bar |

| — | Carrying arm |

| — | Subframe supports (often 4 pcs) |

| — | Transverse stabilizer |

| — | Stretcher |

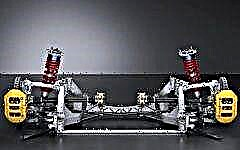

Diagram of a multi-link suspension device

- Rack support;

- Upper levers;

- Swivel stand;

- Telescopic stand;

- Wheel bearing;

- Wheel hub;

- Guide lever;

- Stabilizer bar;

- Carrying lever;

- Subframe supports (often 4 pieces);

- Transverse stabilizer;

- Stretcher.

MacPherson suspension signs and malfunctions

The first and very noticeable malfunction is body rocking... The main sign that the shock absorber struts are exhausting their resource and become unusable. As a result, loss of comfort, deterioration in vehicle handling, as well as accelerated wear of associated suspension parts.

Cars on which ABS and ESP, in the event of a suspension breakdown, they begin to fire and signal more often. As soon as your "iron horse" starts nodding or swaying, then you should not postpone it for later. The result of such breakdowns is a proportional increase in the braking distance, the larger the breakdown, the slower the car will stop. Accordingly, the safety of the car is lost.

Loss of exchange rate stability another reason to pay attention to the car's suspension. The release or weakening of one of the shock absorbers leads to a decrease in the support of the machine on all 4 wheels. Thus, when entering a turn, the car simply skids, the very sliding of any axis indicates a possible breakdown.

At least once in his life, every driver felt on himself like a car nodding or throwing a butt... This usually leads to poor health, decreased attention, or much more striking consequences of such a breakdown. This is another sign of failure of the car's shock absorbers, the buildup itself and the incorrect distribution of the mass of the car is felt during sharp acceleration or braking. It is impossible to sit comfortably in such a car, moreover, all this harms the body structure.

Decrease in ground clearance also a sign of failure of one of the suspension parts, unless of course you are a supporter of "understated" cars, and the car's suspension has not undergone modifications. There may be several reasons for such a breakdown, fatigue metal, corrosion of one of the parts. Most often, springs can sink (reduce the compression stroke), due to which the entire impact force is transmitted to the body and interior of the car, the joints and joints on the body and along the interior expand.

Uneven tire wear and excessive stiffness, it is with these indicators that most suspension problems begin. Tire wear can be seen with the naked eye, and the stiffness will be felt when driving on uneven roads. For the MacPherson suspension, this is a very common phenomenon, due to the floating angle of the wheels (violation of wheel alignment) or the subsidence of the shock absorber as a whole.

Where is the MacPherson suspension installed?

It was mentioned several times above that it is often possible to meet the MacPherson suspension on front-wheel drive cars of the middle and class, on the front axle (less often they are installed on the rear axle). But this is not a strict rule, this type of mechanism can also be found on budget versions of cars, both in the front and in the back. The most popular cars on which you can find MacPherson suspension are presented below.

- Hyundai Creta;

- Mitsubishi Lancer;

- Audi 80;

- VAZ 2109;

- Chevrolet Aveo;

- Volkswagen Passat;

- Ford Focus;

- Nissan Maxima;

- Skoda Octavia;

- Toyota Camry;

- Kia Soul.

This is a minimal list of where the MacPherson suspension is used, so you can find and review it on many cars. Do not be lazy to approach any car and look at the front suspension device in order to fully understand and see the difference with the multi-link.

MacPherson Suspension Parts Price

It is not worth talking about the specific cost of the MacPherson suspension part, since it is different for each car, make and model. Each manufacturer in its own way modifies and produces individual suspension units, respectively, and the price will be different.

Let's take a 2010 Toyota Camry V40 as an example:

| Name | Price from, rub. |

| Shock absorber Sachs | 2011 |

| Front spring Kayaba | 1916 |

| Front shock absorber support FENOX | 1559 |

| Ball joint Quinton Hazell | 726 |

| GSP hub bearing | 1107 |

| Wheel hub PROFIT | 4726 |

Not to say that replacing the named parts will be cheap, but nevertheless, as statistics show, these are the most popular parts that most often fail. The final conclusion is expensive or cheap, everyone can make personally, since it all depends on the driving style and the time between repairs of the car's suspension.

Reviews of the MacPherson suspension

- Much of the McPherson suspension depends on the manufacturer, in some it is softer, others are made stiff. Still, at the cost of maintenance, a multi-link is cheaper, but there is also more noise from it, especially when the shock absorbers disappear.

- Repairing such a suspension is not the most pleasant moment, especially changing the shock absorbers and tightening the springs yourself, but quickly and without special tuning the mechanism. Minus in the wheel alignment, it is advisable to carry it out from time to time. I can say that so far this is the most successful and inexpensive independent type suspension.

- After a car with a multi-link suspension, I will say that McPherson is much cheaper to service. Spare parts are not so expensive, and if you look at it in time, it does not transmit any noise and vibration to the body. In addition, the slightest breakdown is immediately visible, which means the safety of the car is at its best.