The content of the article:

- What is "pneumatics"

- History of creation

- Varieties of construction

- How does the air suspension work?

- Advantages and disadvantages of pneumatics

Today, air suspension is fitted to many SUVs and business class vehicles. Often among car owners there are heated debates about the advantages and disadvantages of "pneumatics". Before drawing any conclusions, it is worthwhile to figure out what the air suspension device is, and how it is good and bad.

What is "pneumatics"

Of course, modern high-quality shock absorbers make it possible to make driving a car with a classic suspension quite comfortable, but this is perhaps all that can be said about the "classic". Whatever elasticity the springs and springs of such a suspension may have, the whole structure retains a high degree of rigidity. This means that the ground clearance (the distance between the bottom and the road surface) of a car equipped with a classic suspension remains unchanged.

The air suspension has the ability to adjust the height of the vehicle body in relation to the road surface.

This element was developed and put into operation to provide the driver with a greater degree of comfort and a high-quality level of safety while driving.

Air suspension is widely used on car trailers and trucks. However, business class cars are also often equipped with "pneumatics" - this gives the model a special status and attracts the attention of those who value safety and convenience, while having the opportunity to purchase such a car.

History of creation

Attempts to equip a car with a suspension operating on a pneumatic basis began at the dawn of the automotive industry - in the twenties of the last century. By 1957, the designers managed to bring the system to an industrial level: the company General Motors began to install it on its Cadillac Eldorado B linkedin... True, at that time the system was not widespread, and the developments were put on the shelf marked "not in demand".

With the passage of time, new technologies have made it possible to revise the original design, and the air suspension has returned to the automotive industry, already in an updated form.

Varieties of air suspension

Pneumatic suspensions differ in the number of circuits:

- single-circuit;

- double-circuit;

- four-circuit.

Single-circuit air suspension mounts on only one vehicle axle, front or rear. Such a system is most often installed on the rear axle of trucks and truck tractors, in order to adjust the rigidity of the rear wheel axle depending on the degree of vehicle load.

Dual-circuit system denotes, in fact, not one, but two types of construction. When mounted on both axles, it essentially does the work of two first type suspensions. But in the case when the suspension is mounted on one axle, along the contour to the wheel, it will adjust the position of each wheel on the axle separately, independently of one another.

Four-circuit air suspensionbut, on the one hand, the most difficult, and on the other, the most effective. Each wheel is equipped with a pneumatic support that adjusts its position independently of the others. The pressure in the pneumatic elements in this design option is usually controlled by a single electronic unit.

Self-installation of the air suspension is not recommended; Only the factory-installed suspension will work flawlessly. This is especially evident in the case of a four-circuit suspension. Some car services offer customers such a service as installing pneumatics, but such work will cost so much that you will inevitably think about buying another car with this money, even with a classic suspension.

How does the air suspension work?

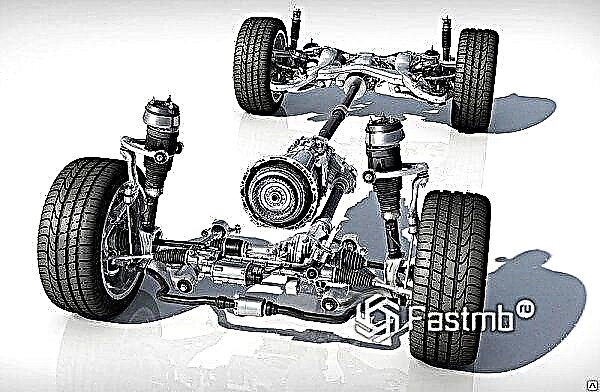

In its simplest form, the air suspension consists of:

- pneumatic elastic element;

- a compressor supplying compressed air;

- air inlet;

- air lines;

- electronic sensors of the system state and vehicle position;

- electronic control unit.

The role of the main mechanisms that regulate and maintain ground clearance is played by elastic pneumatic elements. Their work is regulated automatically or manually by changing the air pressure inside the element.

Modern designs provide for two versions of the pneumatic element: in the form of an autonomous structure or in combination with a shock absorber (pneumatic strut). The second design option can be mounted on any type of suspension.

The basis of the suspension - compressed air, which is forced into the elements by the compressor. Electronic tracking sensors determine the position of the body relative to the roadway and the speed of the vehicle. The received data is sent to the control unit, which regulates the air pressure in the suspension elements.

In a small range, the ground clearance can be regulated by the operation of the receiver (air receiver). In this case, the compressor is not involved in the process.

Manual and automatic air suspension modes

To adjust the position of the vehicle body, the pneumatics can be operated in manual or automatic modes.

Manual mode allows not only to adjust the ground clearance, but also to change the stiffness of the suspension.

The automatic mode of operation takes into account in their work the slope of the surface on which the machine is moving, the speed and acceleration of the movement. If the machine is cornering, the system automatically raises the stiffness of the struts under load.

Advantages and disadvantages of air suspension

Any design has its pros and cons. Let's see what is good and what is bad air suspension.

Air suspension advantages

- The ability to maintain a given vehicle body height under various loads. Even when the load is uneven, the system maintains the correct position of the machine relative to the road surface.

- The ground clearance of a vehicle with air suspension can be changed. This is especially true in situations where you have to travel off-road or on poor-quality roads, which our country is so rich in.

- The pneumatic system provides the vehicle with a smooth ride. It is much more convenient for the driver and passengers to travel in a car with "pneumatics" than in a car with a classic suspension. In addition, the air suspension is very quiet.

- A car equipped with air suspension moves smoothly, without jerking. The body of such a car does not swing, the roll of the car in a turn is minimal. All this contributes to the good handling of the car on the road.

- If the air suspension is mounted on a classic stock one, the factory mounts and springs last longer.

- A car with air suspension significantly increases its mileage. Subject to all the manufacturer's recommendations, such a car can safely go up to 1 million kilometers.

- A car with air suspension has a higher load capacity compared to a car of the same make and class, but with a conventional suspension.

Disadvantages of air suspension

- The first minus of the air suspension is, perhaps, its cost. Modern systems are equipped with a lot of auxiliary functions, such as pneumatic signal, automatic tire pressure increase, etc. This, of course, does not reduce the cost of the design, therefore, in the modern automotive industry, pneumatics are mainly installed on trucks and business class cars.

- The equipment requires constant maintenance: pneumatics do not tolerate dirt, dust and sand, so they have to be constantly monitored and cleaned. Needless to say, in domestic road conditions, this turns into a difficult procedure?

- Air bags are virtually irreparable. Therefore, if the pneumatic element is out of order, it will have to be replaced.

- In the cold, the pneumatics functions with limitations, so that fans of winter trips are unlikely to be able to fully appreciate all the advantages of this design.

- Road reagents, with which we are so fond of treating winter roads, also significantly reduce the life of the mechanisms.

Having evaluated the advantages and disadvantages of air suspension, it can be argued that this design is very relevant for both freight transport and passenger cars. Moreover, the constant improvement in performance makes air suspension more and more in demand and popular.

But, unfortunately, at this level of development of the automotive industry, we have to admit that "pneumatics" are affordable only for those who are ready to invest significant money in a car, and most likely it will be paid attention to by car owners who live in the southern regions of the country, where the frosts are so strong and there are not so many reagents on the roads.